# Dual Motor Testbed v1

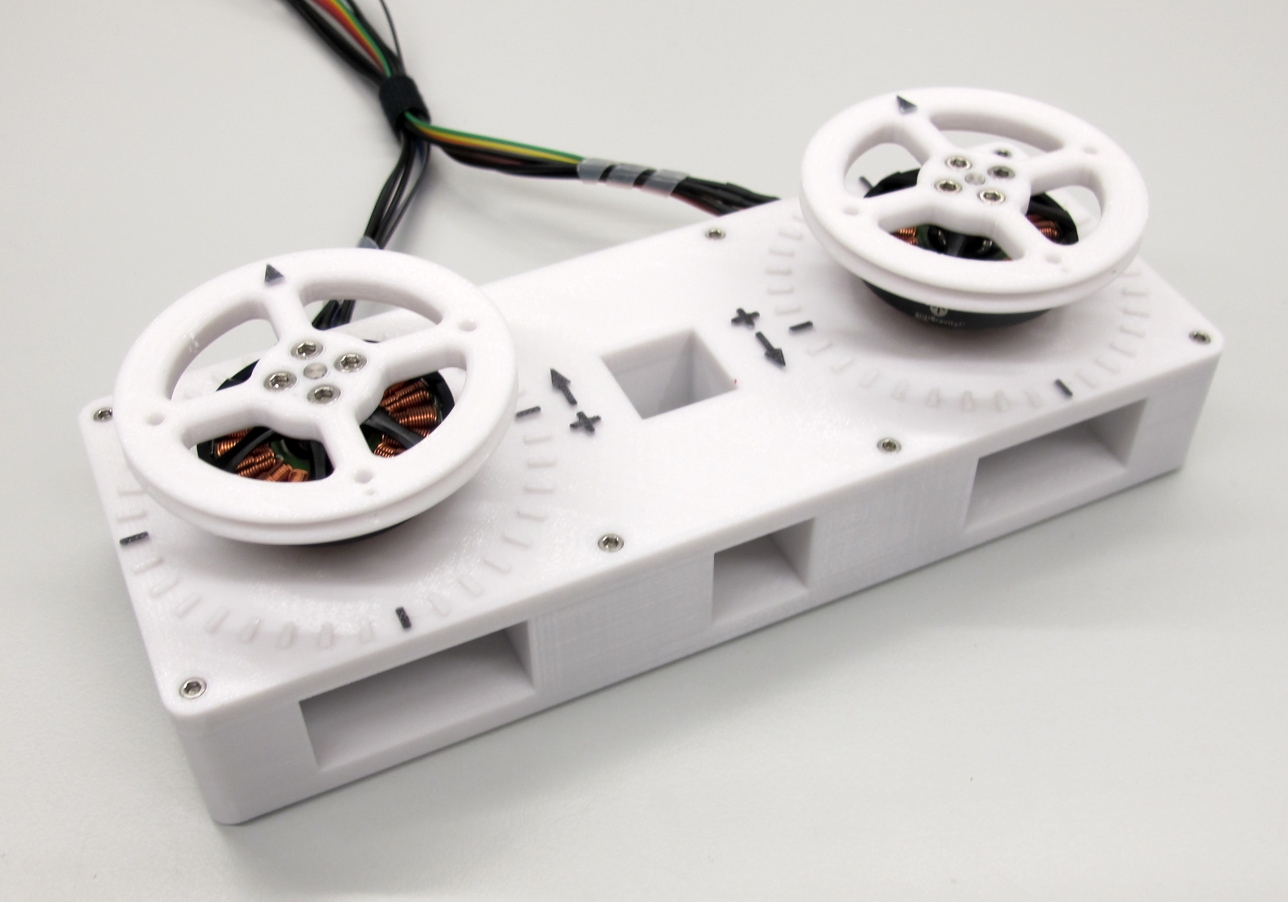

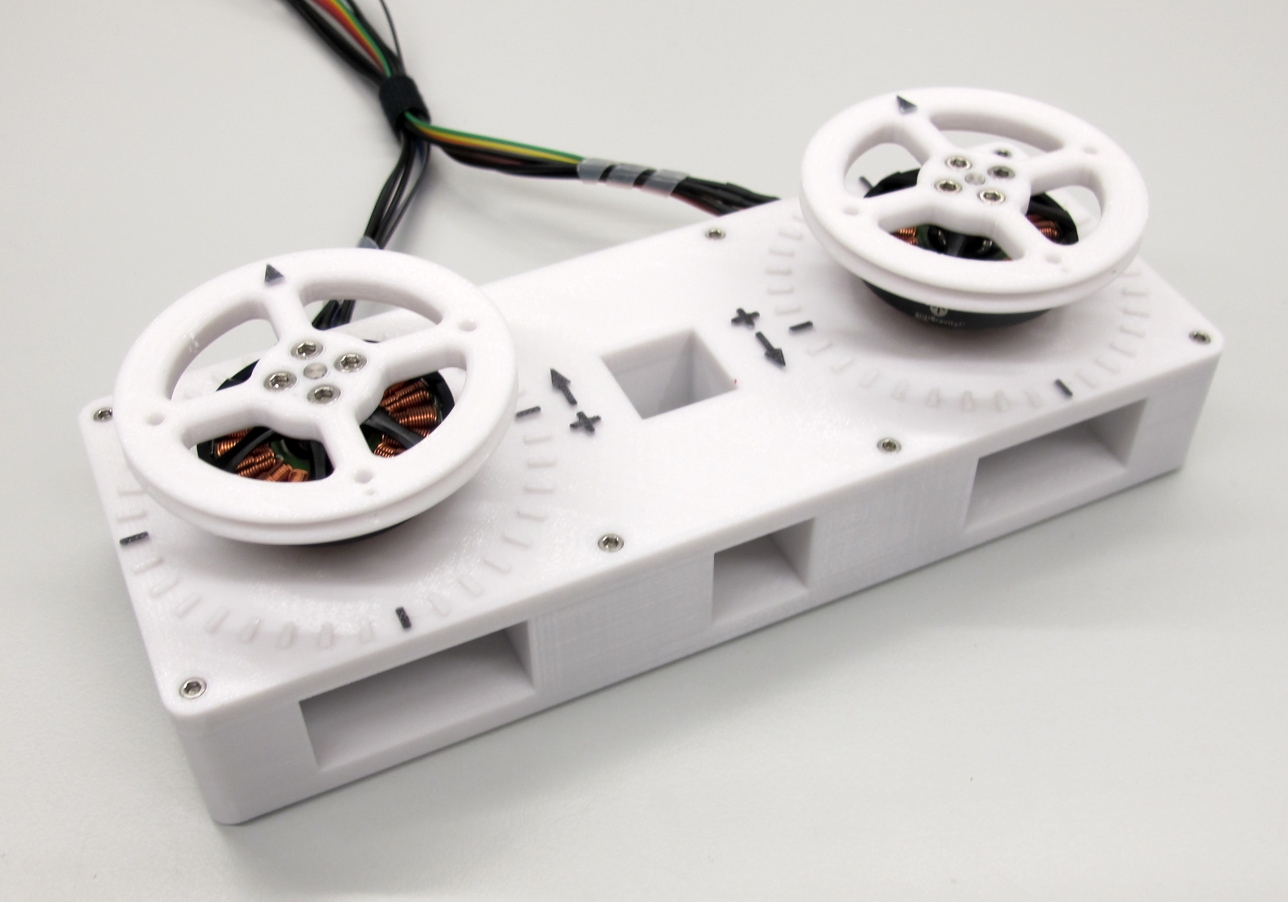

*Dual Motor Testbed consisting of two motors, two encoders and 3d printed parts*

*Dual Motor Testbed with Dual Motor Electronics Box*

*The testbed can be clamped to the table for experiments*

## Description

* this is the simplest mechanical setup to get started with brushless motor torque control

* the testbench consists of two brushless motors and two high resolution encoders mounted directly onto the motor shaft

* the encoders are required for the precise commutation of the motors using field oriented control

* in contrast to "sensorless" control (which the Texas Instruments boards also support) the torque control also works at slow speeds and when the motor is stalled

## Off-the-shelf Components

### Brushless DC Motor

* T-Motor Antigravity 4004 300kV

* 24 magnets / 12 pole pairs / 18 slots

* 3 phase WYE Configuration / Star Configuration

* Rotor diameter: 45mm

* Weight: 53g

* the Antigravity motors are sold in sets of two pieces

* [T-Motor Webpage](http://store-en.tmotor.com/goods.php?id=438)

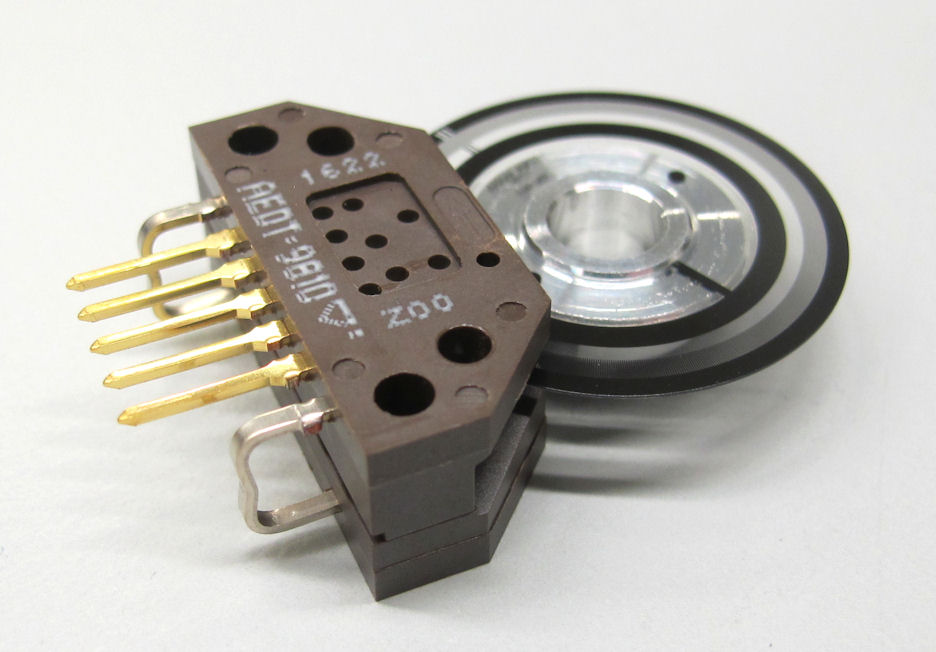

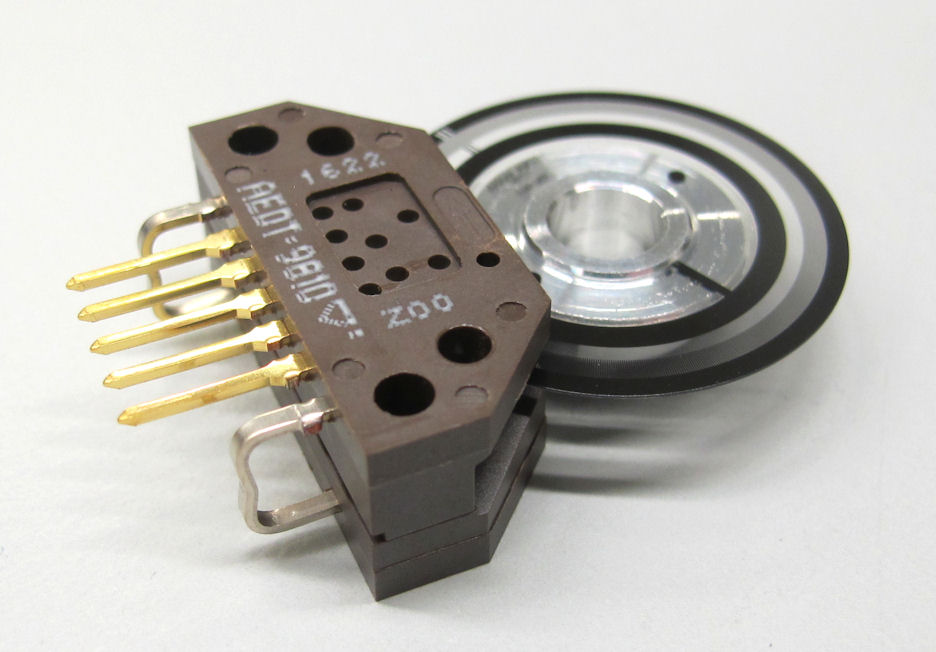

### Optical Encoder

* Broadcom Encoder Kit AEDM-5810-Z12 consisting of the AEDT-9810-Z00 encoder and the high resolution code wheel with index

* 5000 pulses per revolution per channel

* 5V two channel quadrature output with index pulse (ABZ)

* Code wheel diameter: 26mm

* Weight: 5g

* Instructions on how to extract the encoder and the code wheel from the kit can be found here: [Instructions Encoder Kit Disassembly](../actuator_module_v1/details/details_encoder_kit_disassembly.md)

* [Broadcom Encoder AEDT-9810-Z00 Webpage](https://www.broadcom.com/products/motion-control-encoders/incremental-encoders/transmissive-encoders/aedt-981x)

## Machined Parts

*Custom motor shaft made from stainless steel*

* for attaching the codewheel the original motor shaft has to be replaced by this custom motor shaft

* Instructions on how to replace the original motor shaft can be found here: [Instructions Motor Preparation](../actuator_module_v1/details/details_motor_preparation.md)

*Click on picture above to view the PDF drawing*

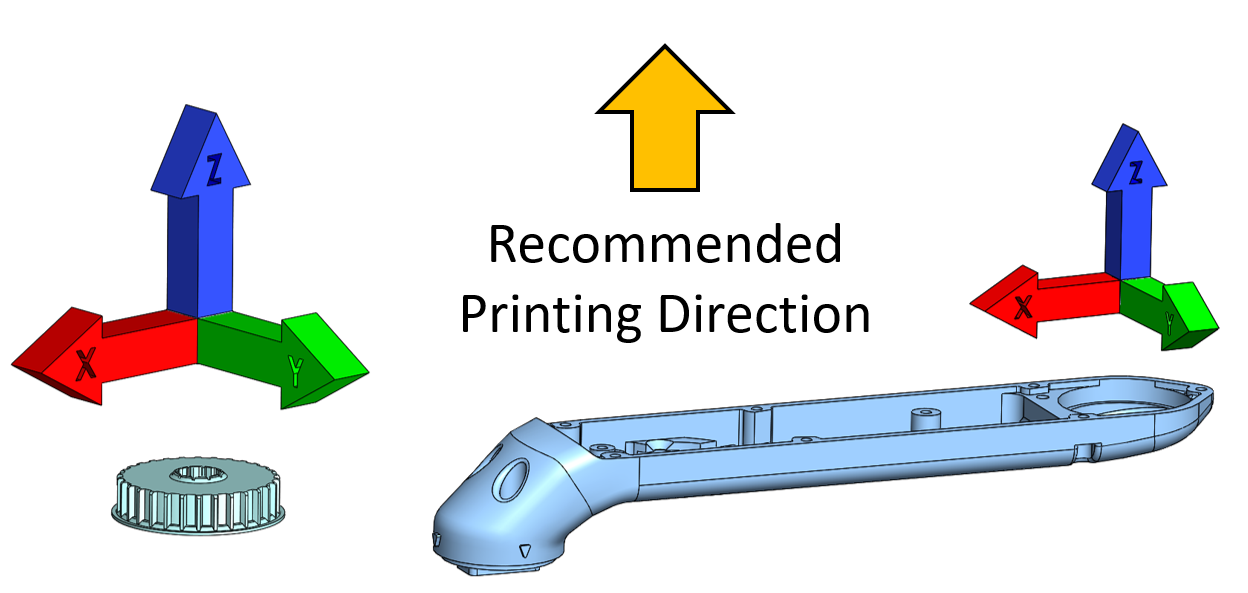

## 3D Printed Parts

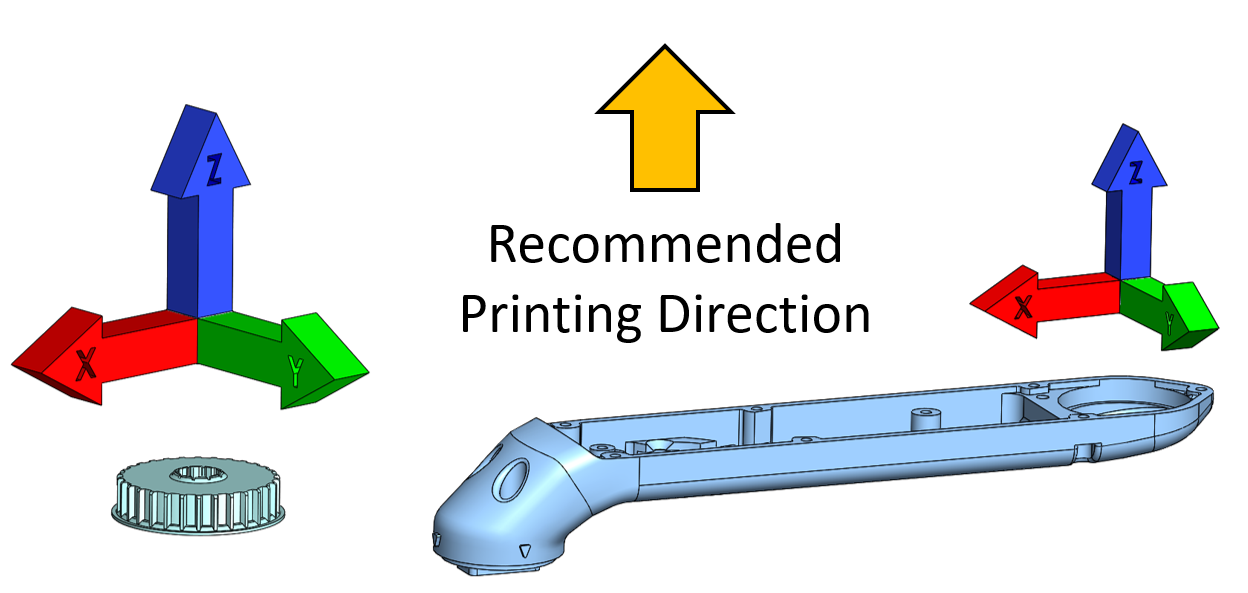

`The recommended printing direction for all the parts below is the positive z direction of the stl files.`

---

* [Dual Motor Testbed Base - STL file](stl_files/dual_motor_testbed_base.STL)

* we print this part with the "sparse double dense" printer setting

* that saves material and print time

* the recommended printing direction is the positive z direction of the stl file

---

* [Dual Motor Testbed Cover - STL file](stl_files/dual_motor_testbed_cover.STL)

* the recommended printing direction is the positive z direction of the stl file

---

* [Encoder Code Wheel Mount - STL file](stl_files/encoder_code_wheel_mount.STL)

* the recommended printing direction is the positive z direction of the stl file

---

* [Hand Wheel - STL file](stl_files/hand_wheel.STL)

* the recommended printing direction is the positive z direction of the stl file

# Bill of Materials - Dual Motor Testbed

| Part Name | Quantity | Ordering Information | Comments |

| --- | --- | --- | --- |

| Brushless Motor | 2 | T-Motor Antigravity 4004 300kV | Sold in set of two pieces |

| Optical Encoder with Codewheel | 2 | Broadcom Encoder Kit AEDM-5810-Z12

| Part Name | Quantity | Ordering Information | Comments |

| --- | --- | --- | --- |

| Brushless Motor | 2 | T-Motor Antigravity 4004 300kV | Sold in set of two pieces |

| Optical Encoder with Codewheel | 2 | Broadcom Encoder Kit AEDM-5810-Z12

Digi-Key 516-3253-ND |[Encoder Kit Disassembly Instructions](../actuator_module_v1/details/details_encoder_kit_disassembly.md#details-encoder-kit-disassembly) |

| Custom Motor Shaft | 2 | [PDF Drawing](details/motor_antigravity_4004_custom_shaft.PDF) | Machined part |

| Testbed Base | 1 | [STL file](stl_files/dual_motor_testbed_base.STL) | 3d printed part |

| Testbed Cover | 1 | [STL file](stl_files/dual_motor_testbed_cover.STL) | 3d printed part |

| Code Wheel Mount | 2 | [STL file](stl_files/encoder_code_wheel_mount.STL) | 3d printed part |

| Hand Wheel | 2 | [STL file](stl_files/hand_wheel.STL) | 3d printed part |

| Rubber Feet | 6 | RS 236-509 | Optional |

| Fasteners Stator and Hand Wheel | 16 | Socket Head Cap Screw M3x6 | Stainless steel |

| Fasteners Testbed Cover | 8 | Socket Head Cap Screw M2,5x8 | Stainless steel |

| Fasteners Code Wheel Mount | 4 | Set Screw M3x4 | Stainless steel |

| Fasteners Encoder | 4 | Flat Head Phillips Screw M3x16

Conrad 839967 | Nylon |

# Dual Motor Electronics Box

*Dual Motor Electronics Box*

## Off-the-shelf Components

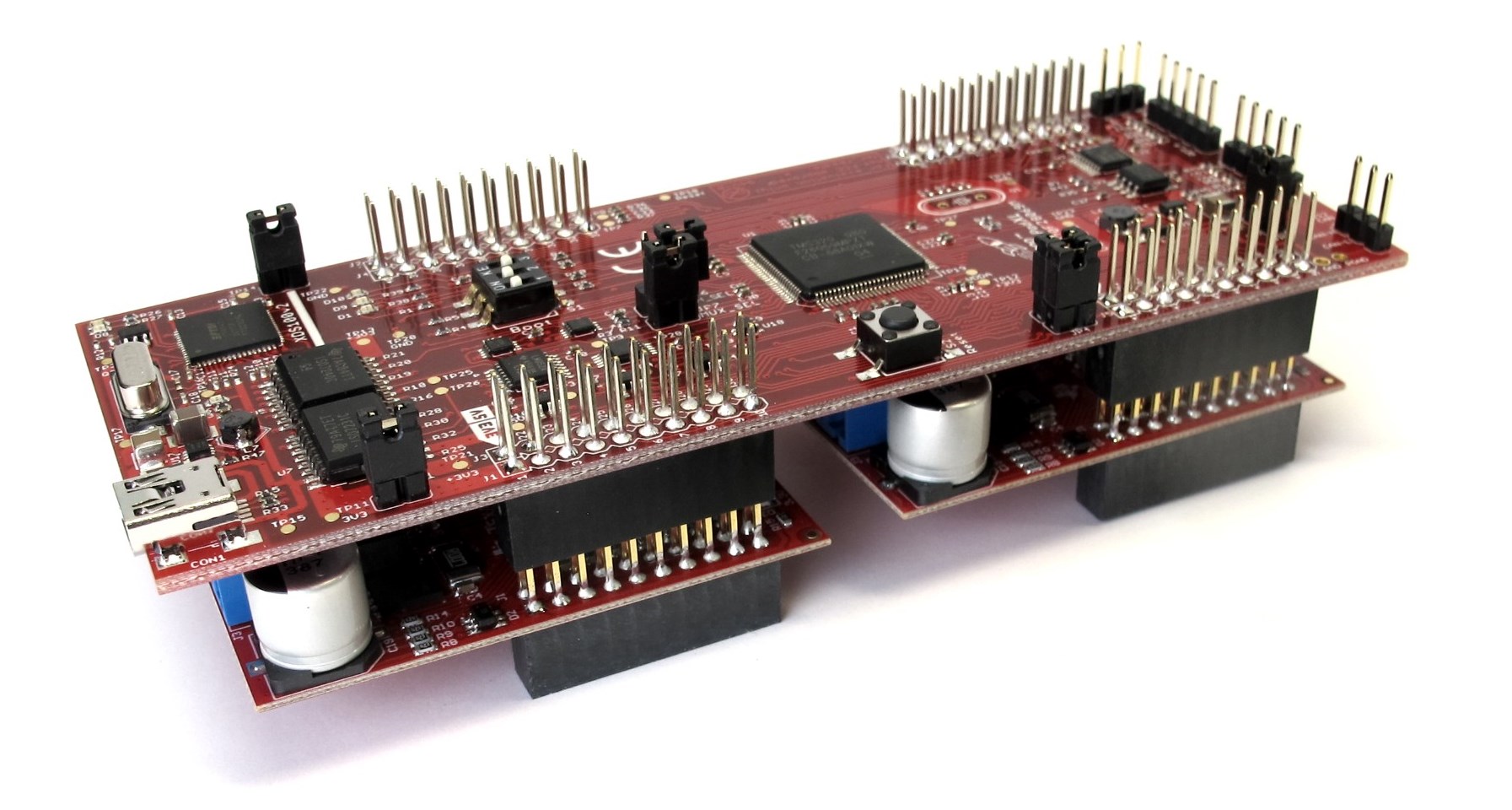

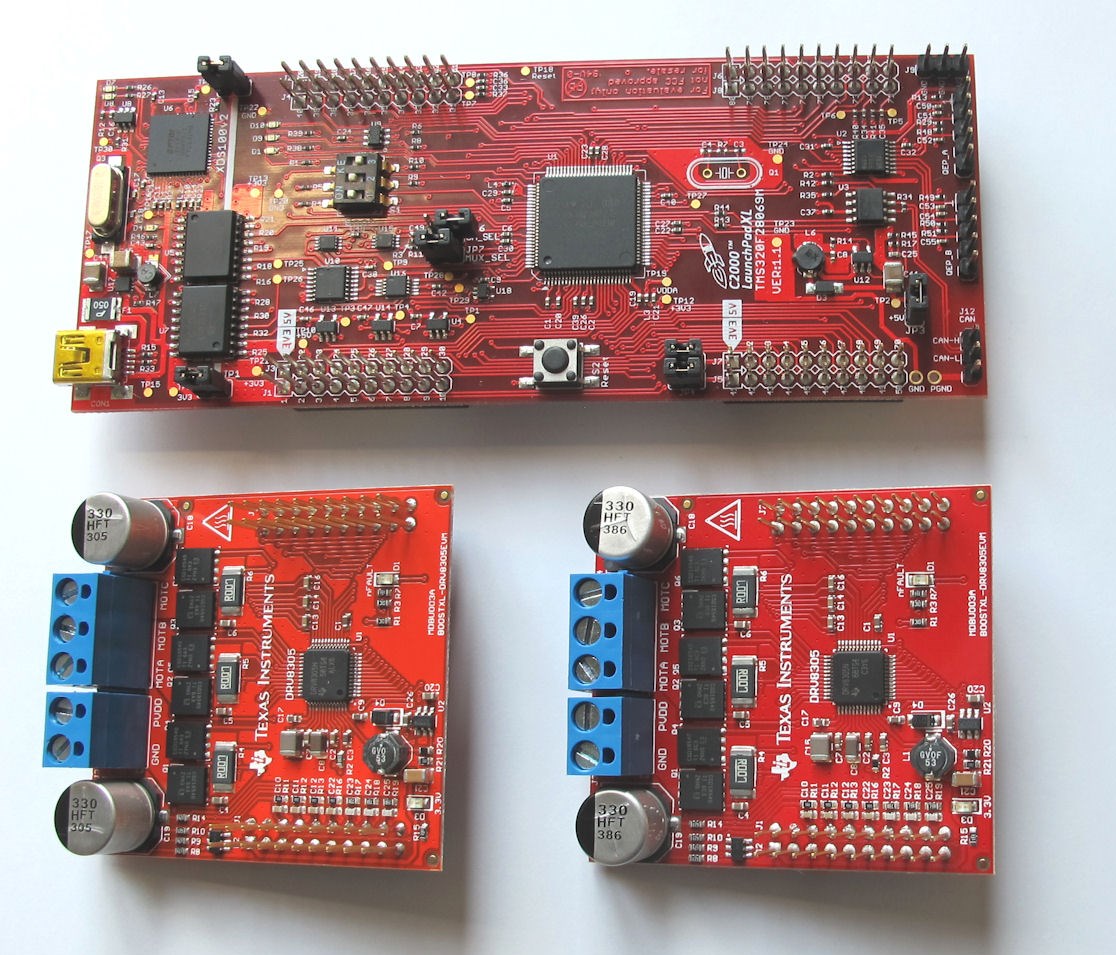

### Texas Instruments Dual Motor Evaluation Boards

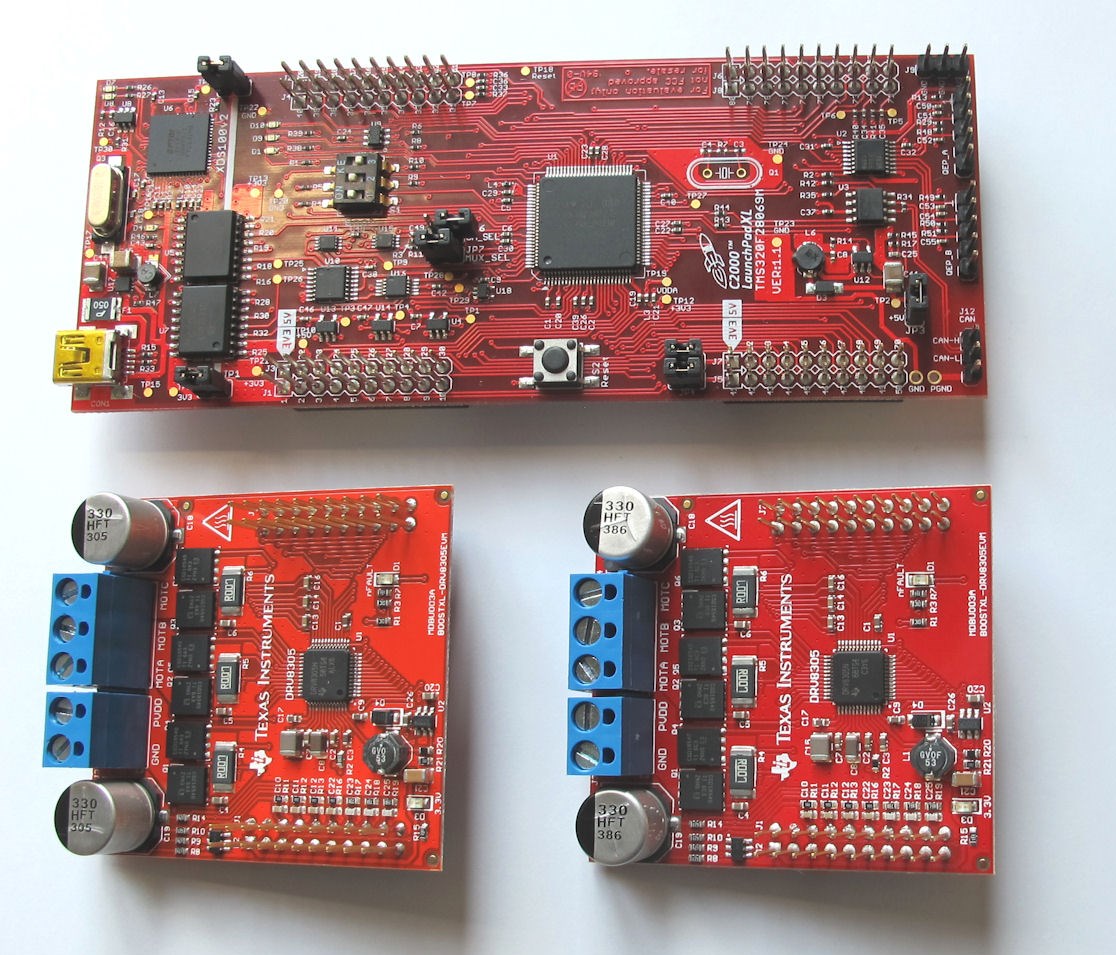

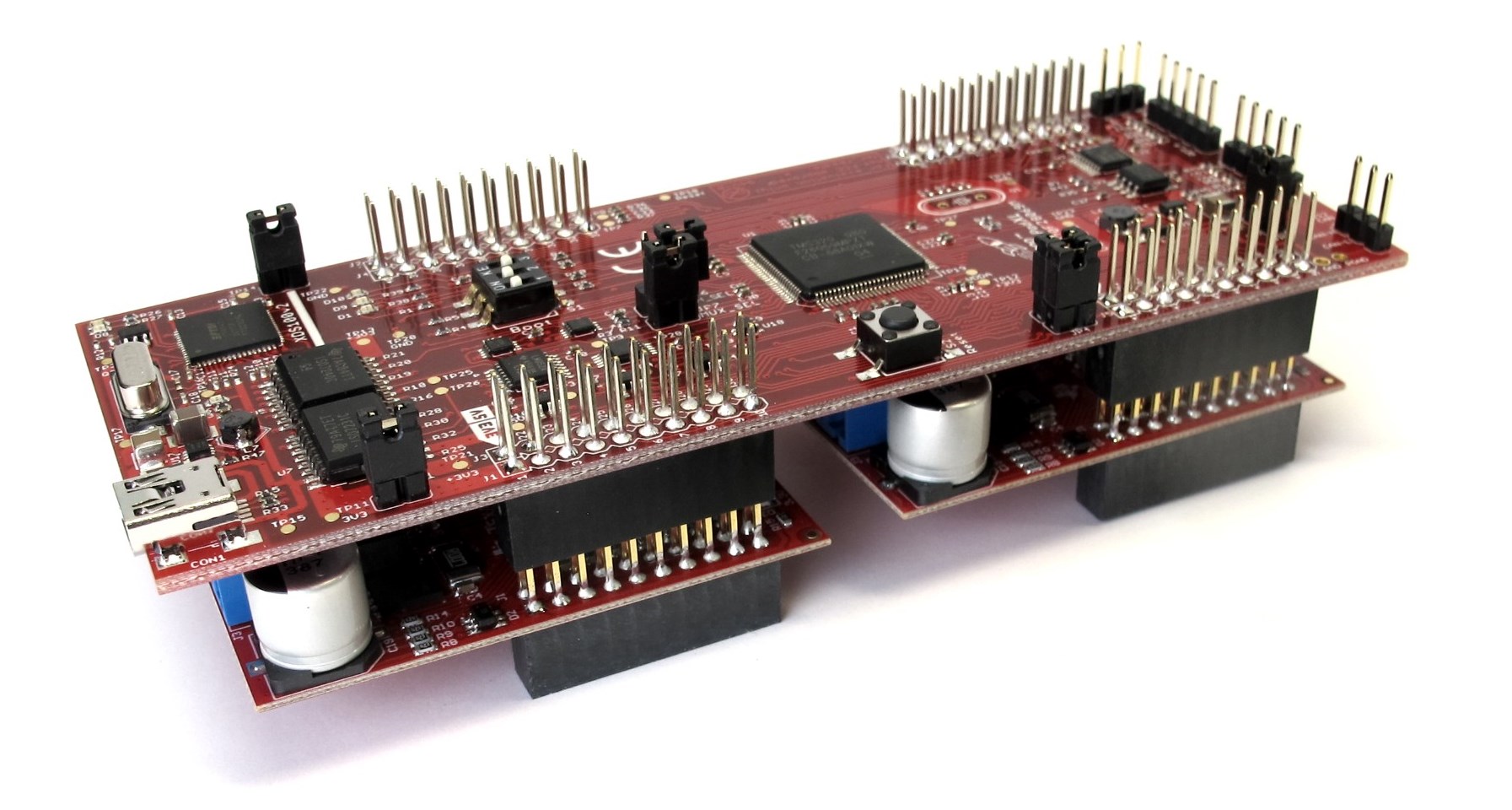

*Texas Instruments dual motor control electronics stack*

*Components dual motor control electronics stack*

* 1 x Microcontroller: TI Launchpad F28069M -> [Launchpad Product Page](http://www.ti.com/tool/LAUNCHXL-F28069M)

* 2 x Motor Driver Card: TI Boosterpacks DRV8305 -> [Booster Pack Product Page](http://www.ti.com/tool/BOOSTXL-DRV8305EVM)

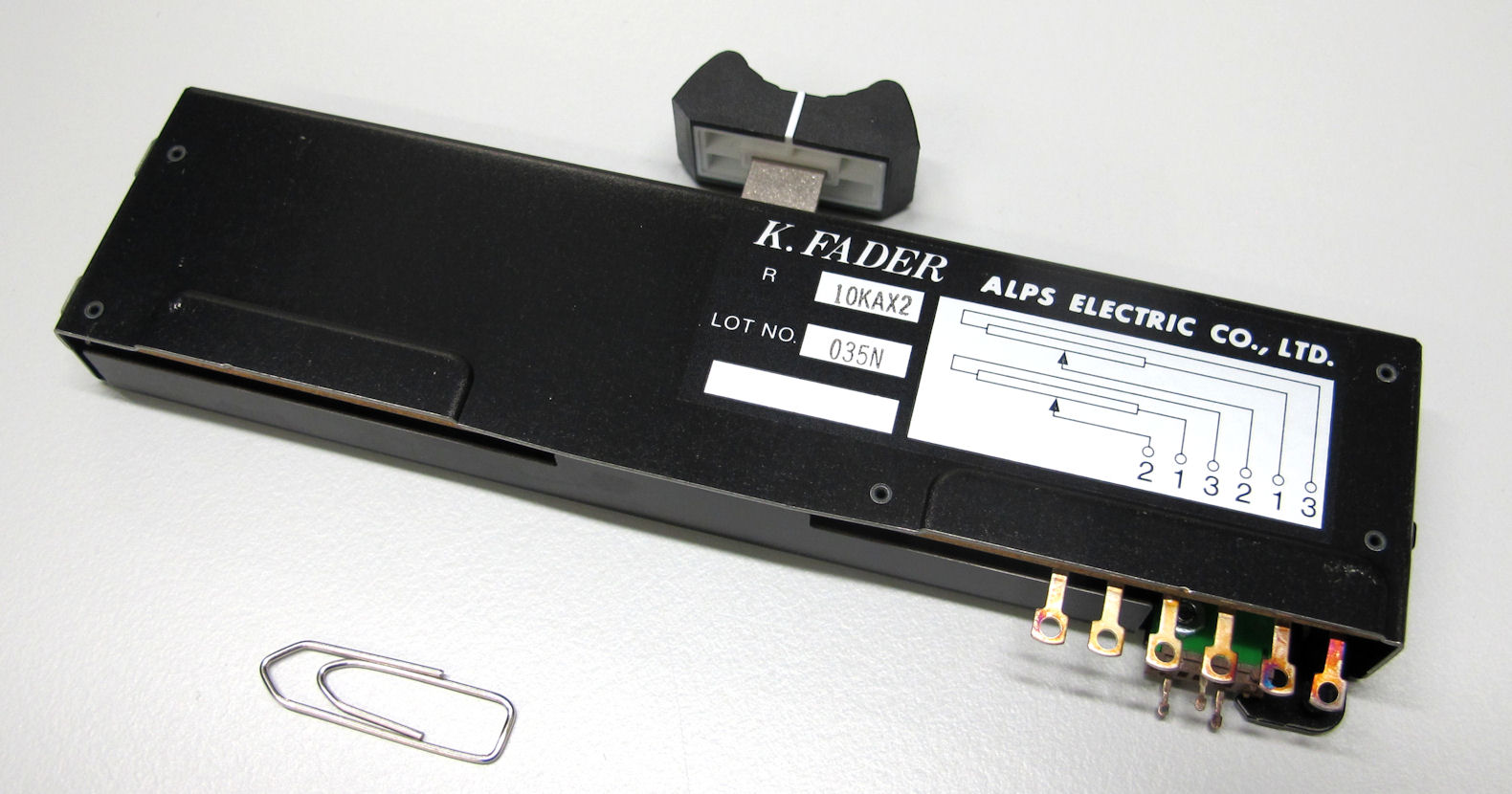

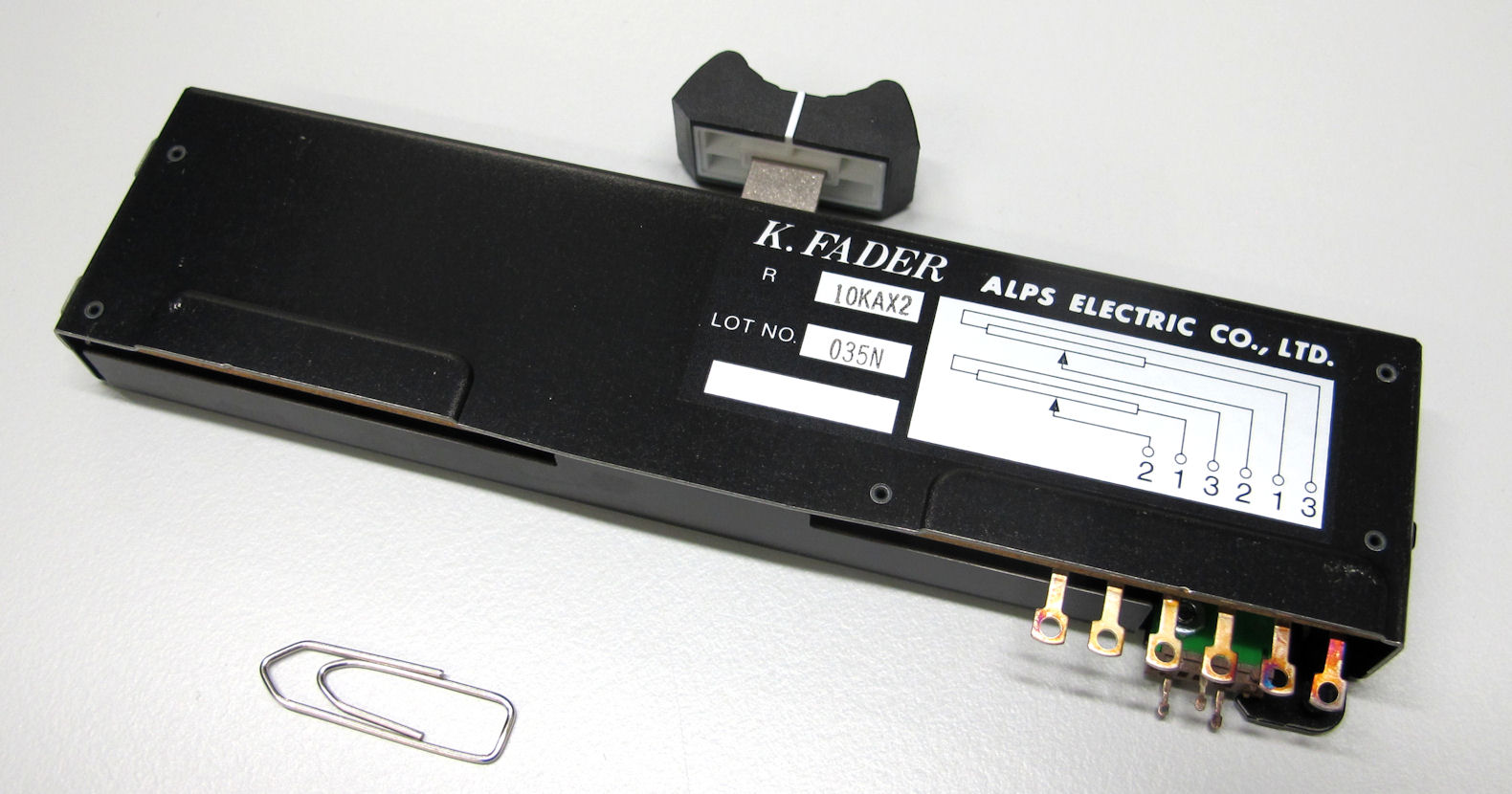

### Analog Linear Potentiometers

* Linear potentiometer 10 kohm

* Alps Alpine RSA0K12B1019

### E-Stop Switch

* E-stop switch 32mm

* Pilz 84-5040.0040

### Power Supply

* Power Supply 24V

* Meanwell GST90A24

### CAN Card

* PEAK PCAN PCI Express Card

* dual channel - galvanically isolated

### CAN Connector

* 9 pole D-Sub connector

## 3D Printed Parts

* [Dual Motor Electronics Box Base - STL file](stl_files/electronics_box_base.STL)

* the recommended printing direction is the positive z direction of the stl file

---

* [Dual Motor Electronics Box Cover - STL file](stl_files/electronics_box_cover.STL)

* the recommended printing direction is the positive z direction of the stl file

# Bill of Materials - Dual Motor Electronics Box

| Part Name | Quantity | Ordering Information | Comments |

| --- | --- | --- | --- |

| Texas Instruments Microcontroller | 1 | TI Launchpad F28069M

| Part Name | Quantity | Ordering Information | Comments |

| --- | --- | --- | --- |

| Texas Instruments Microcontroller | 1 | TI Launchpad F28069M

Digi-Key 296-38832-ND| [Launchpad Product Page](http://www.ti.com/tool/LAUNCHXL-F28069M) |

| Texas Instruments Motor Driver Electronics | 2 | TI Boosterpack DRV8305EVM

Digi-Key 296-43181-ND | [Booster Pack Product Page](http://www.ti.com/tool/BOOSTXL-DRV8305EVM) |

| Linear Potentiometer | 2 | Alps Alpine RSA0K12B1019

RS 234-6544 | |

| Linear Potentiometer Knob | 2 | RS 281-7197 | |

| E-Stop Switch | 1 | Pilz 84-5040.0040

RS 690-6954 | |

| Power Supply 24V | 1 | Meanwell GST90A24

RS 880-8427 | |

| Electronics Box Base | 1 | [STL file](stl_files/electronics_box_base.STL) | 3d printed part |

| Electronics Box Cover | 1 | [STL file](stl_files/electronics_box_cover.STL) | 3d printed part |

| Fasteners Linear Potentiometer | 4 | Flat Head Screw M3x10 | Stainless steel |

| Fasteners Electronics Box Cover | 4 | Socket Head Cap Screw M2,5x8 | Stainless steel |

| Rubber Feet | 6 | RS 236-509 | Optional |

| CAN PCI Express Card | 1 | PEAK IPEH-003027 | Dual channel |

| CAN Connector | 1 | 9 pole D-Sub connector

RS 765-9555 | |

## View the dual motor testbed cad model in your web browser

*Dual Motor Testbed - Click on the picture to view the cad model in your browser*

## CAD Files

The Solidworks CAD files are available here: [Dual Motor Testbed v1 Solidworks CAD files](solidworks_files/dual_motor_testbed_v1.zip)

## More Information

[Open Dynamic Robot Initiative - Webpage](https://open-dynamic-robot-initiative.github.io)

[Open Dynamic Robot Initiative - YouTube Channel](https://www.youtube.com/channel/UCx32JW2oIrax47Gjq8zNI-w)

[Open Dynamic Robot Initiative - Forum](https://odri.discourse.group/categories)

[Open Dynamic Robot Initiative - Paper](https://arxiv.org/pdf/1910.00093.pdf)

[Hardware Overview](../../README.md#open-robot-actuator-hardware)

[Software Overview](https://github.com/open-dynamic-robot-initiative/open-dynamic-robot-initiative.github.io/wiki)

## Authors

Felix Grimminger

## License

BSD 3-Clause License

## Copyright

Copyright (c) 2019-2021, Max Planck Gesellschaft and New York University

| Part Name | Quantity | Ordering Information | Comments |

| --- | --- | --- | --- |

| Brushless Motor | 2 | T-Motor Antigravity 4004 300kV | Sold in set of two pieces |

| Optical Encoder with Codewheel | 2 | Broadcom Encoder Kit AEDM-5810-Z12

| Part Name | Quantity | Ordering Information | Comments |

| --- | --- | --- | --- |

| Brushless Motor | 2 | T-Motor Antigravity 4004 300kV | Sold in set of two pieces |

| Optical Encoder with Codewheel | 2 | Broadcom Encoder Kit AEDM-5810-Z12

| Part Name | Quantity | Ordering Information | Comments |

| --- | --- | --- | --- |

| Texas Instruments Microcontroller | 1 | TI Launchpad F28069M

| Part Name | Quantity | Ordering Information | Comments |

| --- | --- | --- | --- |

| Texas Instruments Microcontroller | 1 | TI Launchpad F28069M